Landvio High Temperature Resistant

Dust Removal Ceramic Fiber Filter

Functional Overview

The Landvio High-Temperature Ceramic Fiber Filter is designed to fully replace baghouse dust collectors (bag filter), electrostatic precipitators, and other conventional dust removal systems. It achieves ultra-low emission purification for industrial kiln exhaust gases and enables efficient removal of acidic components such as SO₂, HF, and HCl when combined with desulfurization agents. Its distinctive advantage lies in operating continuously within a broad temperature range of 150–900°C while maintaining high filtration efficiency, minimal maintenance, and exceptional reliability.

- Performance Specifications

- Dust Removal Efficiency: >99% (typical particulate emission concentration <5 mg/m³, with a minimum achievable level of 1 mg/m³

- Acid Removal Efficiency: >95% (typical emission <50 mg/m³)

- Temperature Adaptability

- Low-Temperature Range: ≤200°C, with excellent water resistanc

- Medium-Temperature Range: 200–600°

- High-Temperature Range: 600–900°C, with high mechanical strength

- Filtration Principle & Operation

- The filter is constructed by uniformly stacking over 100 layers of ceramic fiber fabric, forming a nested pore structure with diameters of 25–45 nanometers. This design physically blocks particulate matter across multiple size classes, including PM10, PM2.5, and PM1.0. Its filtration efficiency for sub-micron particles (e.g., PM1.0) significantly outperforms traditional systems like baghouses or electrostatic precipitators

- A pulsed valve system periodically injects high-pressure air to dislodge accumulated dust from the tube surface into a ash collection hopper. Installation and operation methods are similar to those of conventional baghouse filters, ensuring compatibility with existing infrastructure

Process Technology

Utilizing core proprietary technologies, all raw materials and processes are 100% independently developed and localized in China

- Raw Cotton Fiber Processing

- Centrifugal Lamination Molding of External Molds

- Intelligent Drying

- Secondary Curing and Precision Grinding

Key Features

This product delivers high filtration efficiency, is easy to maintain, and offers safe and reliable operation across various complex working environments. It can be optionally equipped with an intelligent leak detection system for the filters

- ultra-low emission standards.

- wide temperature range.

- long-term, maintenance-free reliable operation.

- ultra-low pressure drop for further energy savings and cost reduction.

Applications

Widely used in industrial kilns and furnaces:

- Glass Kilns

- Waste Incineration & Power Generation

- Industrial Boilers

- Iron & Steel Industry

Show cases

Production Workflow

Materials

Cottom Preparation

This product utilizes custom-formulated ceramic fiber cotton with high alumina content, which strictly controls impurities beyond alumina and silica. It specifically eliminates contaminants such as Na, K, Mg, and Ga that are prone to causing vanadium-titanium catalyst poisoning and deactivation.

The high-alumina characteristic ensures the ceramic filters exhibit exceptional high-temperature resistance, while the low-impurity feature prevents the nano-catalyst from being easily poisoned and deactivated, thereby maintaining its activity.

-

- Al 2O 3 > 45-48%

- SiO 2 > 51-54%

- Al 2O 3+SiO 2 > 99.6%

- Na、K、Mg、Ga < 0.3%

Cotton Processing

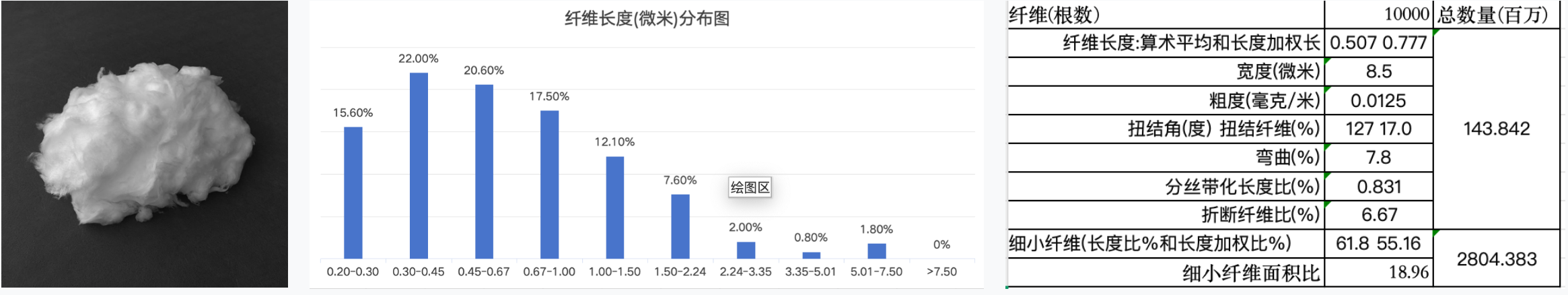

The processing of ceramic fiber raw cotton utilizes nationally patented technology with independent intellectual property rights. This proprietary process ensures uniform fiber length distribution, compliant fiber diameter, and low shot content in the resulting ceramic fiber material.

Precisely Controlled Physical Parameters (e.g., length distribution, diameter range) of the ceramic fibers guarantee uniform spraying and prevent agglomeration during the formation of the ceramic filter coating. It enhances the strength of the filter tubes, and ensures the uniformity of the laminated pore structure as well.

Quality Inspection

Comprehensive testing of raw materials is conducted for parameters such as fiber diameter, length distribution, shot content, and bulk value. The inspection process covers raw material receiving, in-process sampling, and post-processing centralized inspection.

-

- Ceramic Fiber Diameter: 2.5-3.5um

- Fiber Shot Content(212um): < 8-15%

- Bik Value:200±40

Bik Value is a key indicator for measuring fiber dispersibility and slurry-forming capability. It refers to the volume of a unit mass of fiber under specific conditions, reflecting the fiber's loftiness and ability to form a slurry. A higher value indicates fluffier fibers and better dispersion

Molding Process

External Mold Forming

Ceramic filters are formed using external molds. The outer surface retains the impression marks from the mold, which enhances the adsorption efficiency of desulfurizing agents and prevents particles from penetrating the tube surface, thereby reducing clogging risks.

The pore size of the external mold gradually increases from the exterior to the interior, facilitating efficient cleaning via reverse blowing. This design not only improves purification efficiency but also reduces operational costs.

Ultrafiltration Characteristics

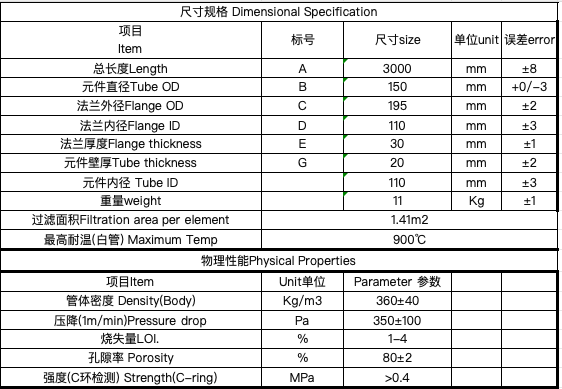

The axial lamination molding process employs centrifugal force to uniformly layer fiber slurry, ensuring even wall thickness distribution (without agglomeration). The final product comprises over 100 laminated layers, guaranteeing high mechanical strength.

The filter exhibits a porosity >80%, with ceramic fiber laminated pore sizes ranging from 25–45 nm. The pressure drop remains <300 Pa (at 1 m/min airflow)

Nanoscale Pore Engineering

While a single layer of filter material has micron-scale pores, the uniform stacking of over 100 layers achieves nanoscale pore structures. This not only enhances the filter's strength but also enables ultra-efficient filtration of millimeter-, micron-, and even submicron-sized particles.

The nanoscale pores significantly prolong the flue gas residence time within the filter tube, providing a critical foundation for high-efficiency denitrification in catalytic filter systems

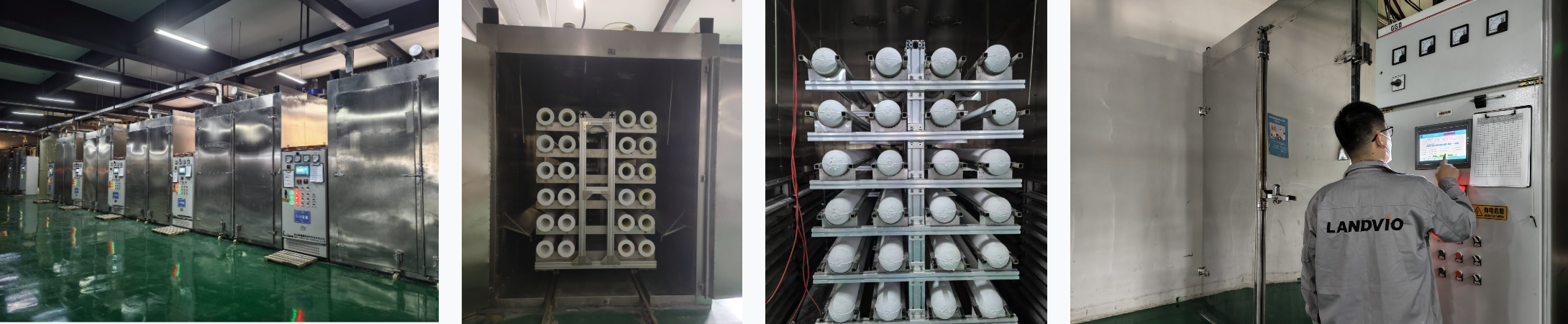

Drying & Curing

Customized dryerss are employed for the curing and drying of molded ceramic filters. An automatic control system precisely regulates the drying temperature curve across different sections of the ceramic tubes and throughout various stages of the process. This ensures that each part of the ceramic filter remains within the optimal temperature range at all times, preserving the structural integrity of the filter and maintaining its high strength properties.

Commitment to Green Factory Initiatives for Energy Savings and Carbon Reduction. By implementing advanced automatic control systems, the drying time for ceramic filter tubes has been reduced from 35–40 hours to 15–20 hours, cutting energy consumption costs by 50%. Furthermore, the introduction of external natural heat sources during summer months further lowers energy usage and production costs.

Grinding & Curing

Precision Grinding

Precision grinding strictly controls the flatness of the flange to ensure uniform stress distribution during operation. Flange flatness directly affects whether the installed filters bear loads evenly. Filters under uneven stress are prone to fracture at the points of maximum pressure, compromising service life and filtration performance.

Deep Curing

The flange and the adjacent 150–200 mm section of the tube are the most vulnerable areas prone to fracture during use. With a flange thickness of 30 mm, conventional curing typically achieves a depth of less than 10 mm (often only 6–8 mm), leaving a 10–15 mm uncured "core" in the center. This results in insufficient flange hardness and increased risk of operational damage. Our ceramic filters employ deep curing technology, reducing the uncured core to <10 mm (typically 5–8 mm), significantly enhancing flange strength and extending service life. Additionally, the front end of the flange, which withstands significant reverse-jet stress, undergoes the same deep curing process to prevent severe internal wear from long-term pulsed cleaning.

C-Ring Strength

C-ring strength is measured by cutting a 50 cm ring sample from the ceramic filter, creating a C-shaped specimen with an approximately 50° opening. The maximum pressure required to crush the sample under radial compression is recorded.

The industry standard for ceramic filters requires a minimum C-ring strength of ≥0.35 MPa. Compared to the industry's average and maximum C-ring strengths, Our ceramic filters guarantee a minimum C-ring strength exceeding 0.4 MPa, which is 14% above the standard requirement.

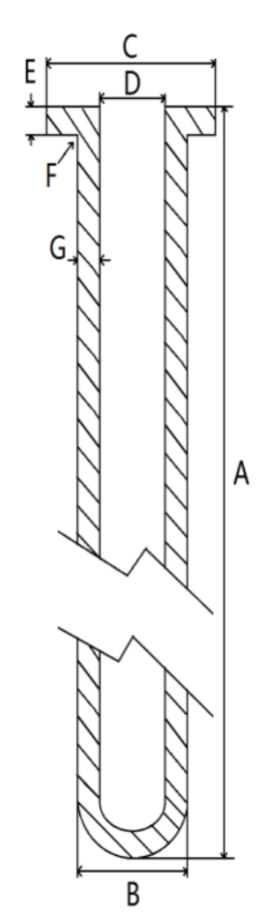

Installation

The installation sequence is gasket → ceramic filter tube → venturi tube → pressure plate, with distance tubes used to prevent over-tightening and damage to the flange

The venturi tube serves to guide the reverse-jet airflow, enhancing dust removal efficiency

The orifice plate typically has an inner diameter of 152 mm (for a filter tube outer diameter of 150 mm), and features a chamfered design to prevent damage during installation