Landvio NOx Reduction Catalytic Ceramic Filter

Functional Overview

The Landvio Desulfurization & Denitrification Ceramic Catalytic Filter can completely replace traditional denitrification methods like SCR catalysts, achieving ultra-low emission treatment for industrial kiln exhaust gases. It also uses urea or ammonia as a reducing agent and can consistently achieve a denitrification efficiency exceeding 95%. By integrating ceramic technology with desulfurizing agents, it enables highly efficient removal of acidic components such as SO₂, HF, and HCl, with a removal efficiency of >95% . Furthermore, within the temperature range of 220-260°C, it can decompose up to 99% of dioxins without requiring additional reactants or generating solid waste throughout the process.

It's able to to operate within a broad temperature range of 220-400°C while maintaining high removal efficiency for NOx, acidic components, and dioxins, along with high reliability and minimal maintenance requirements.

- Purification Performance

- Dust Removal Efficiency: >99% (Typical particulate emission concentration <5 mg/m³, can reach as low as 1 mg/m³)

- Denitrification Efficiency: >95% (Typical <200 mg/m³, can reach <10 mg/m³)

- Desulfurization Efficiency: >95% (Typical <50 mg/m³)

- Dioxin Removal Efficiency: ≥99%

- Other Acidic Components Removal Efficiency: ≥95%

- Operating Temperature Ranges

- Low-Temperature Range: 220-280°C, Denitrification efficiency >95%

- Medium-Temperature Range: 280-400°C, Denitrification efficiency >95%

- How it works

- Desulfurizing agents like lime powder or sodium bicarbonate are used to neutralize and remove acidic components such as SO₂, HF, and HCl. The dense structure of the ceramic filter ensures excellent adhesion of the desulfurizing agent on its surface, increasing reaction time. Meanwhile, its nano-scale pores provide physical filtration, trapping particles, reaction salts, and unreacted agents on the tube surface. Timed pulse-jet cleaning using high-pressure air removes the accumulated particles from the ceramic filter surface, blowing them into a ash hopper. The installation and usage method are similar to baghouse filters .

- Urea or ammonia is used as the reducing agent, fully mixed with the flue gas (via atomizing spray guns and static mixers if necessary). By the time the gas reaches the ceramic filter wall, it is essentially dust-free clean air. The unique structure of the ceramic filter, featuring over 100 layers of superimposed material, forces the flue gas to make vertical contact with the filtering material. The non-straight-through micropores also increase the gas's travel path within the tube, extending the reaction time significantly compared to SCR catalysts—by severalfold to over tenfold—thus enabling a removal efficiency exceeding 95% .

- Within the 220-260°C range, dioxins are directly decomposed by the catalyst into harmless small molecules. This entire process requires no additional reactants and produces no solid waste. According to test data from renowned international manufacturers, the decomposition efficiency can reach up to 99%.

Process

Utilizing our independently developed and proprietary core technology, we achieve 100% self-sufficiency in all raw materials and processes, ensuring complete localization

- Processing and Molding

- Deep and Uniform Nano-Catalyst Impregnation

- Intelligent Drying

- Rigorous Quality Inspection and Careful Packaging

Features

High Filtration Efficiency, Easy Maintenance, Safety, and Reliability: Designed to adapt to various complex working environments. An intelligent filter tube leak detection system is available as an optional accessory.

- Ultra-Low Emission Standards

- Broad Temperature Adaptation

- Long-Term, Maintenance-Free Reliability

- Ultra-Low Pressure Drop

Applicatons

Widely used in industrial kilns and furnaces:

- Glass Kilns

- Waste Incineration & Power Generation

- Industrial Boilers

- Iron & Steel Industry

Show cases

Production Workflow

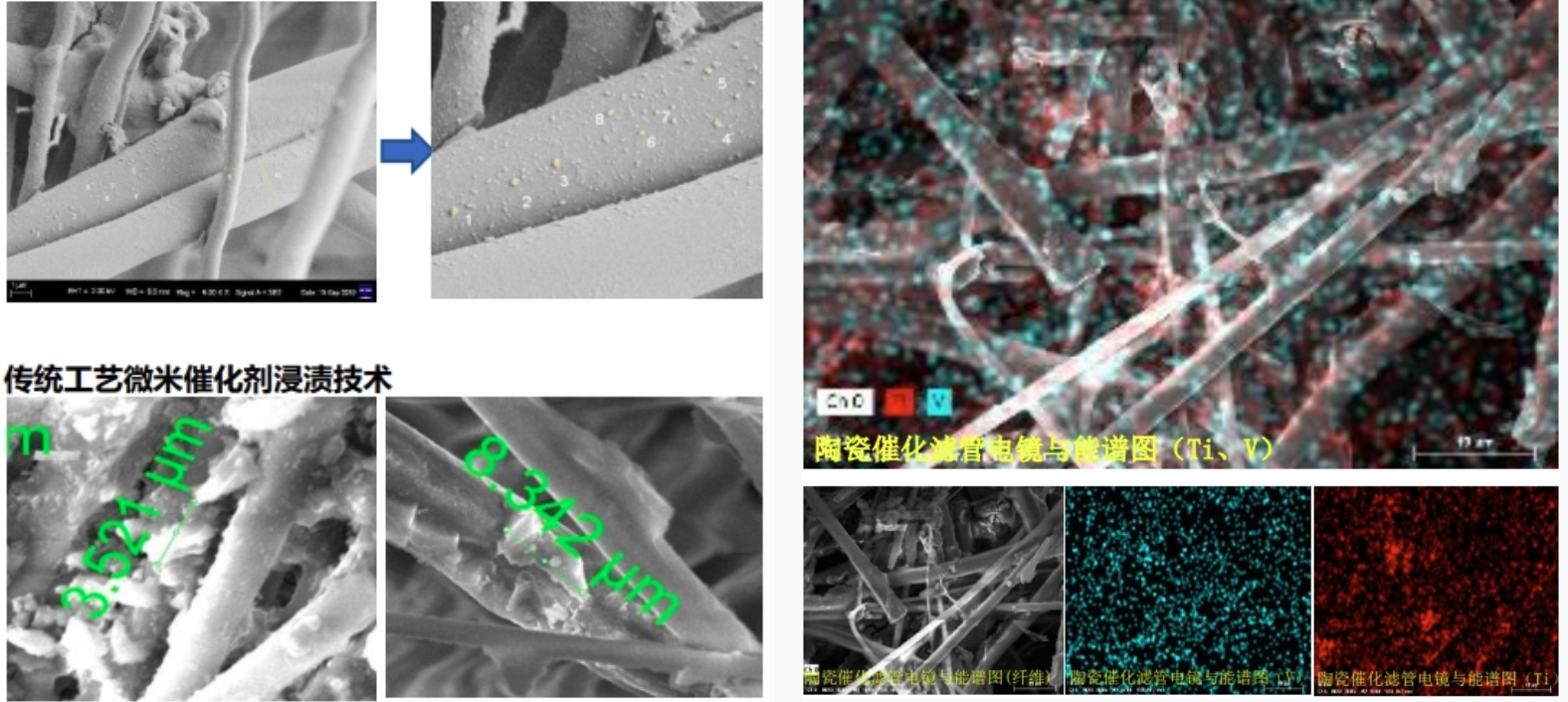

Deep Impregnation of Nano-Catalysts

Nano-Catalysts

Traditional catalyst impregnation processes typically achieve only micrometer-level catalyst attachment. Landvio utilizes vanadium-titanium nanomaterials as supports to form a uniform suspension, with the active component possessing a D50 particle size of approximately 100 nm. These particles have a specific surface area as high as 80 m²/g.

The manufacturing process of the vanadium-titanium catalyst is strictly controlled to ensure that vanadium pentoxide (V⁵⁺) is the primary valence state. This avoids the need for an additional conversion step from V⁴⁺ to V⁵⁺ during catalysis. Using a self-developed dryer with automated temperature curve control ensures uniform drying, resulting in an attractive golden-yellow color in the ceramic catalytic filters.

Deep and Uniform Impregnation

Based on ceramic fiber filter, a nano-catalyst slurry is used for deep impregnation. The impregnation process is meticulously controlled to ensure the catalyst is evenly distributed. Dynamic deep impregnation exceeds 6 hours, achieving an average catalyst distribution within <0.1 µm. The catalyst is uniformly distributed across over 100 layers of filter paper, ensuring thorough impregnation.

High-Efficiency Performance

Rigorous material choose and a unique nano-pore structure prevent the ceramic catalytic filters from experiencing catalyst poisoning issues common in SCR systems. Occasional reductions in denitrification efficiency can be resolved through online high-temperature catalyst regeneration. The denitrification efficiency exceeds 95%, with typical emission concentrations ranging from 50-200 mg/m³.

Integrated with ceramic monolithic technology, the system can simultaneously achieve desulfurization, denitrification, dust removal, dioxin removal, and elimination of acidic components like HF/HCl. This integrated ceramic process, when combined with environmental service providers, enables dry desulfurization, catalytic denitrification, high-temperature dust removal, and the removal of dioxins and other acidic components within a single unit. It can completely replace traditional multi-stage processes involving baghouse dust removal + dry/wet desulfurization + SCR denitrification. Compared to multi-stage processes, it offers lower costs, reduced footprint, higher system reliability, and simpler operation and maintenance

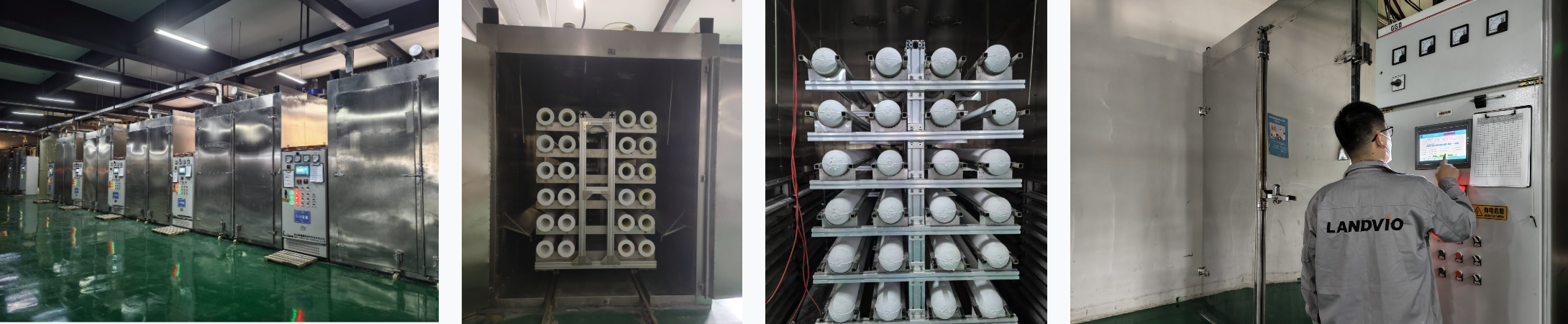

Drying & Curing

Customized dryerss are employed for the curing and drying of molded ceramic filters. An automatic control system precisely regulates the drying temperature curve across different sections of the ceramic tubes and throughout various stages of the process. This ensures that each part of the ceramic filter remains within the optimal temperature range at all times, preserving the structural integrity of the filter and maintaining its high strength properties.

Commitment to Green Factory Initiatives for Energy Savings and Carbon Reduction. By implementing advanced automatic control systems, the drying time for ceramic filter tubes has been reduced from 35–40 hours to 15–20 hours, cutting energy consumption costs by 50%. Furthermore, the introduction of external natural heat sources during summer months further lowers energy usage and production costs.

QC & Packaging

At every stage of production, the quality control department inspects the relevant quality parameters of the semi-finished products to ensure high-quality output. Upon completion of manufacturing, each batch of ceramic filter elements undergoes rigorous checks for strength, pressure drop, porosity, density, appearance, and dimensions, with an inspection report issued accordingly. This stringent, full-process quality control not only guarantees product quality but also generates a unique, tamper-proof, and traceable quality record.

Installation

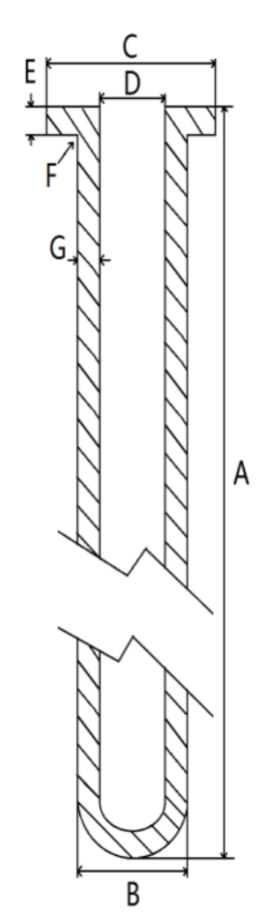

The installation sequence is gasket → ceramic filter tube → venturi tube → pressure plate, with distance tubes used to prevent over-tightening and damage to the flange

The venturi tube serves to guide the reverse-jet airflow, enhancing dust removal efficiency

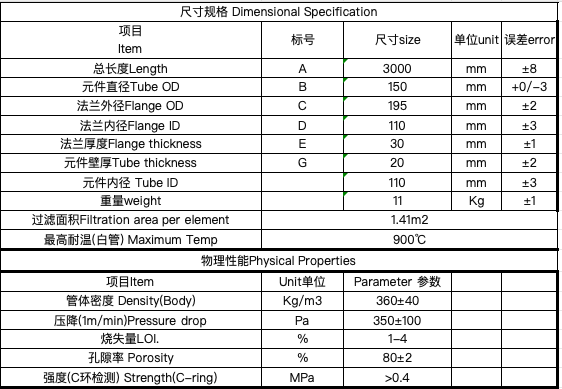

The orifice plate typically has an inner diameter of 152 mm (for a filter tube outer diameter of 150 mm), and features a chamfered design to prevent damage during installation